Repairs

A random tweaks blog

I've had to do some assorted repairs and modifications of stuff as we break and need stuff here, not enough in each for a single blog, so I lumped them together here.

Ryobi pruning shears. (Brushless secateurs).

These guys became intermittent over the course of a heavy pruning day in Temecula, and then just stopped shortly after. We are going to need them shortly as some leaves have started to turn and drop. The apple and pear trees are going to need a LOT of work on them.

Since they are brushless and somewhat expensive ($120ish USD) they were more than worth taking the time for me to open them up and poke around a bit.

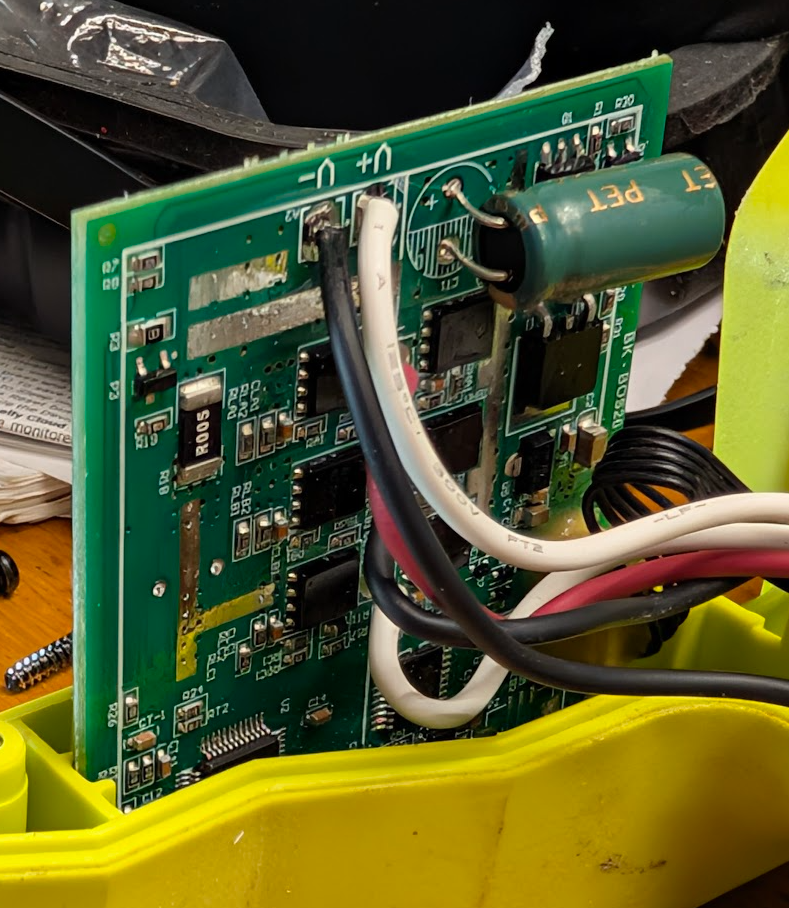

I went straight to the PCB in the lower part of the body, near the battery.

Just checked for dry joints and the like at first.

It all looked good, so I put a battery in and checked for 18v and 5v and even found a 3.3v rail, so that part cleared the sanity check.

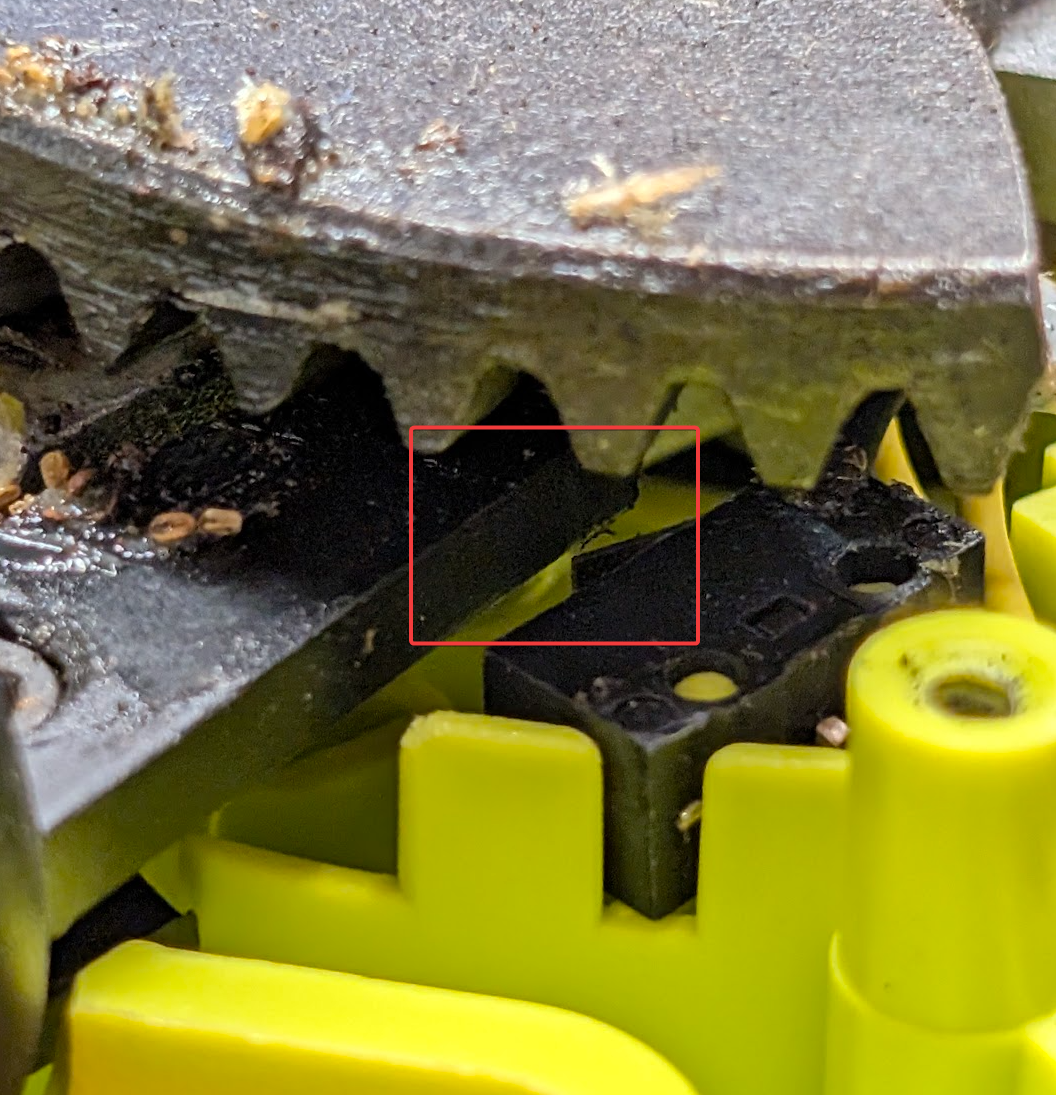

Looking at the other end of the unit, I quickly found the issue.

The top of the trigger was totally missing the micro switch that drives the shear action.

Hard to photograph, but the end of the trigger is above the center of the micro switch arm.

The core issue is that the plastic was worn around the single bolt pivot point.

I did a quick fix of putting a washer in to center it, but it really needs a bigger diameter bolt or sleeve to better center it.

I will have to revisit this one next year when I have my workshop unpacked, but it should get us through the apple tree autumn prune, and if it fails again, I will know exactly where it needs tweaking.

Fun side note, they use the teeth on the main gear as position feedback for the brushless motor drive. Pretty cool.

Reverse osmosis water filter leak.

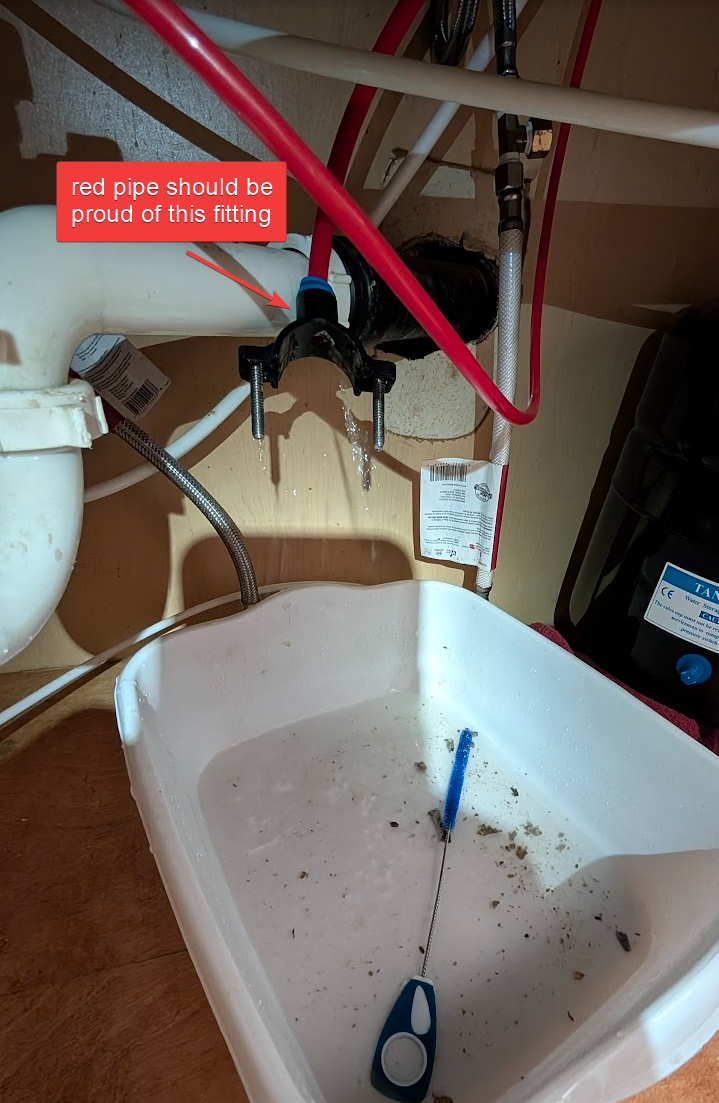

We wondered why there was a water leak detector under the sink with mostly flat batteries when we moved in... Now we know.

Thankfully, this one started at random mid-morning while we were home.

Turned out to be a fairly easy fix. Whoever installed it didn't follow the instructions, and the red drain pipe was just sitting on the top of the while drain, and as expected, it clogged up with gunk. It should be poking INTO the drain by about 1/2 an inch. I suspect that the installer did not have the right-sized drill and so just made do.

I drilled out the hole in the top of the white drain pipe, inserted the red hose, and then tightened the clamp. No issues for the past 4ish weeks.

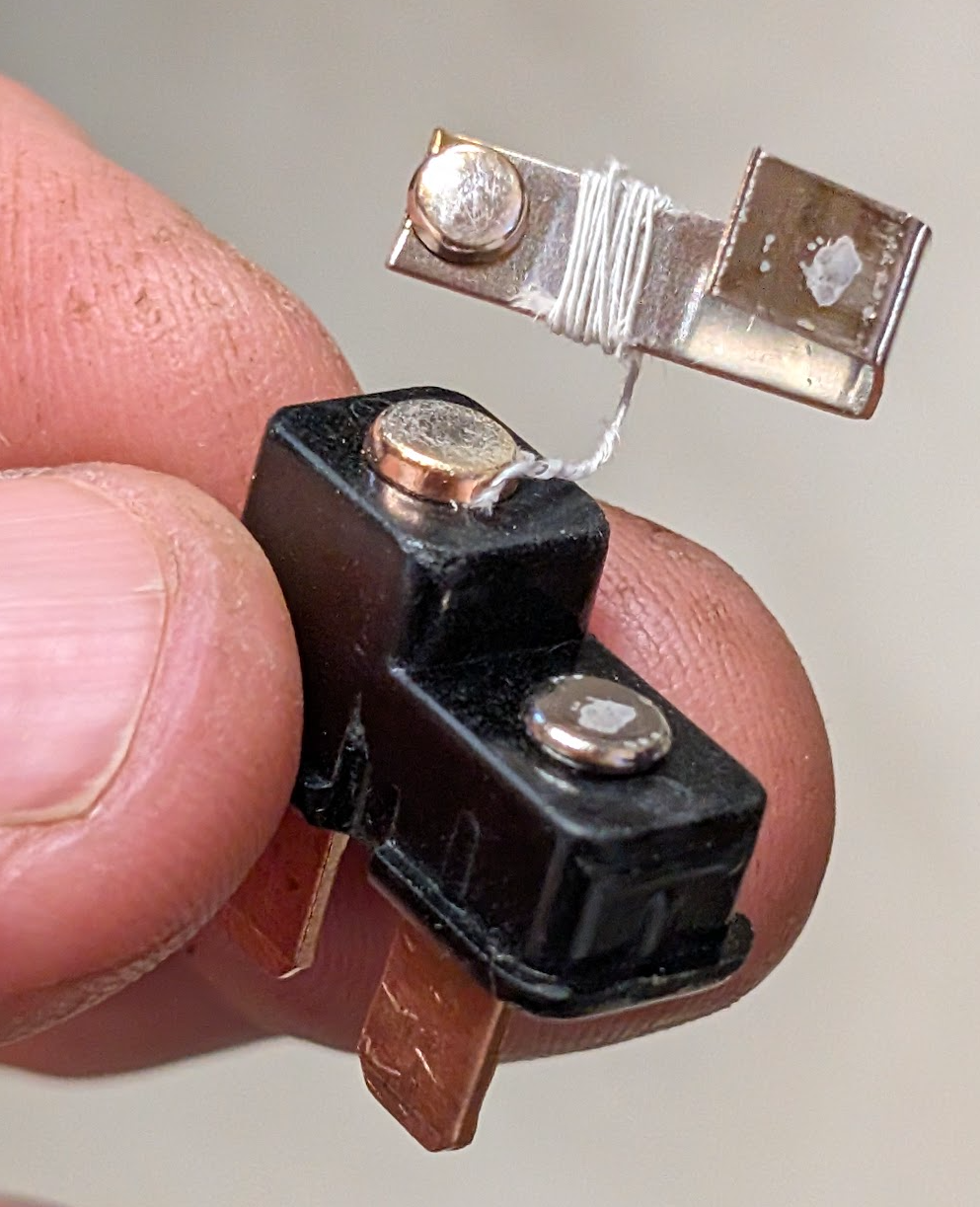

Self-resetting thermal fuse.

The neighbour wanted to put electric seats in his car that he was tinkering with.

The seat worked fine on the bench, but was in-opp when installed in the car.

One other guy spent about an hour on it, and so they finally talked to me about it.

Got it going in about 5 minutes.

Checking the voltage on the car battery showed 12.5v. At the seat 12.5v.

Turn the seat on, and we saw 0v at the seat and 12.5v at the battery.

So I knew something, somewhere, was going open circuit under load.

Checking back through the harness with my ultra-sharp multimeter probe showed the same volts/no volts all the way to the fuse box.

They told me which fuse it was, and straight away, I said, "That's not a fuse". It was a silver can, not the usual plastic blade fuse job.

Pulled the can and put in a 10-amp fuse, and the seat works fine.

I brought it home and opened it up.

Really hard to see, but it must have just been touching, as we did get 12v through it with no load, but as soon as a load was on, it could not pass any current, so it went open.

Anyway, happy neighbour.

Circuit breaker ID tools

What breaker is any given power point connected to?

Plug the remote unit into the outlet, wave the wand over the breaker panel, and find out which one lights up. Yeah. Nah.

I borrowed the Milwaukee (red in the middle) from a mate, thinking this would be a one-afternoon job, so not worth the money to buy one of my own. I spent about 2 weeks waving this thing over my breaker panel, on and off, chasing down each one. It just was not very accurate at all. I've mostly given up for now. A job for when Dan is here, perhaps.

I felt bad I had his tool for so long, so I bought the orange Kline tools on the left.

It's pretty much junk in finding the breaker, but the remote tester is pretty sweet with a voltage readout and ground fault timing.

I was also sick of trying to find live wires, so bit the wallet and bought the Fluke on the very right. It does both jobs fine. No voltage readout on the remote, but easy to see the LEDs across the room, finds the breaker much more accurately, but not perfectly, and also has a live wire non-contact function, which is really handy.

110vAC - specifically why 12-gauge wire

Short rant before I get to the last mod...

I soooooooo hate that the USA had 110vAC forced on it for greed.

It means that me and 10's of thousands of others have to fight with 12-guage wire.

Edison and Tesla were dueling out the whole DC (Edison) and AC (Tesla) and which was safer.

Long bitter war later, Edison finally admitted that transformers could step up and down AC better than DC, so he figured if he had to have AC, it would be as low a voltage as possible (Thus sort of proving he was right). Pretty much the rest of the world chose 240vAC (220).

Half the voltage means twice the current for the same amount of power; that sort of current means thick wires are required. Hence, ugly, stiff, arthritis-inducing 12-gauge wire is used everywhere over here.

To ease the poor electrician's life, push-in termination GPOs were invented; however, they tend to loosen over time, which is why they are generally frowned upon.

So here we are, pretty much every GPO in the house needs to be replaced and loops bent into said 12-gauge and put in under the screws, and thus done right for the next few decades.

My hands are so sore after just a few hours of working with them.

Long-term blog readers might recall the retelling here of my first experience of buying an extension cord from a hardware store back in 2008... I picked it up and straight away my mind went "What in the world??!!! Why is this so heavy!" It took me a second to click back then: half the voltage, twice the current, thicker, heavier, more expensive wires. Thanks Edison /s.

Get me started on why 50Hz was chosen here vs the global 60Hz... Go on!

Ok, then.... Edison did not want European equipment to work in the USA, thus protecting his manufacturing business.

Phone camera tripod adaptor.

I need to record a self-video and could not find the box that had my old, janky plastic phone to tripod adaptor that I was deeply unhappy with, but it sort of worked.

I got a metal one via Amazon, and while I checked its opening size and knew it was about 3mm short, I figured I could make it work on my Pixel 9 Pro XL.

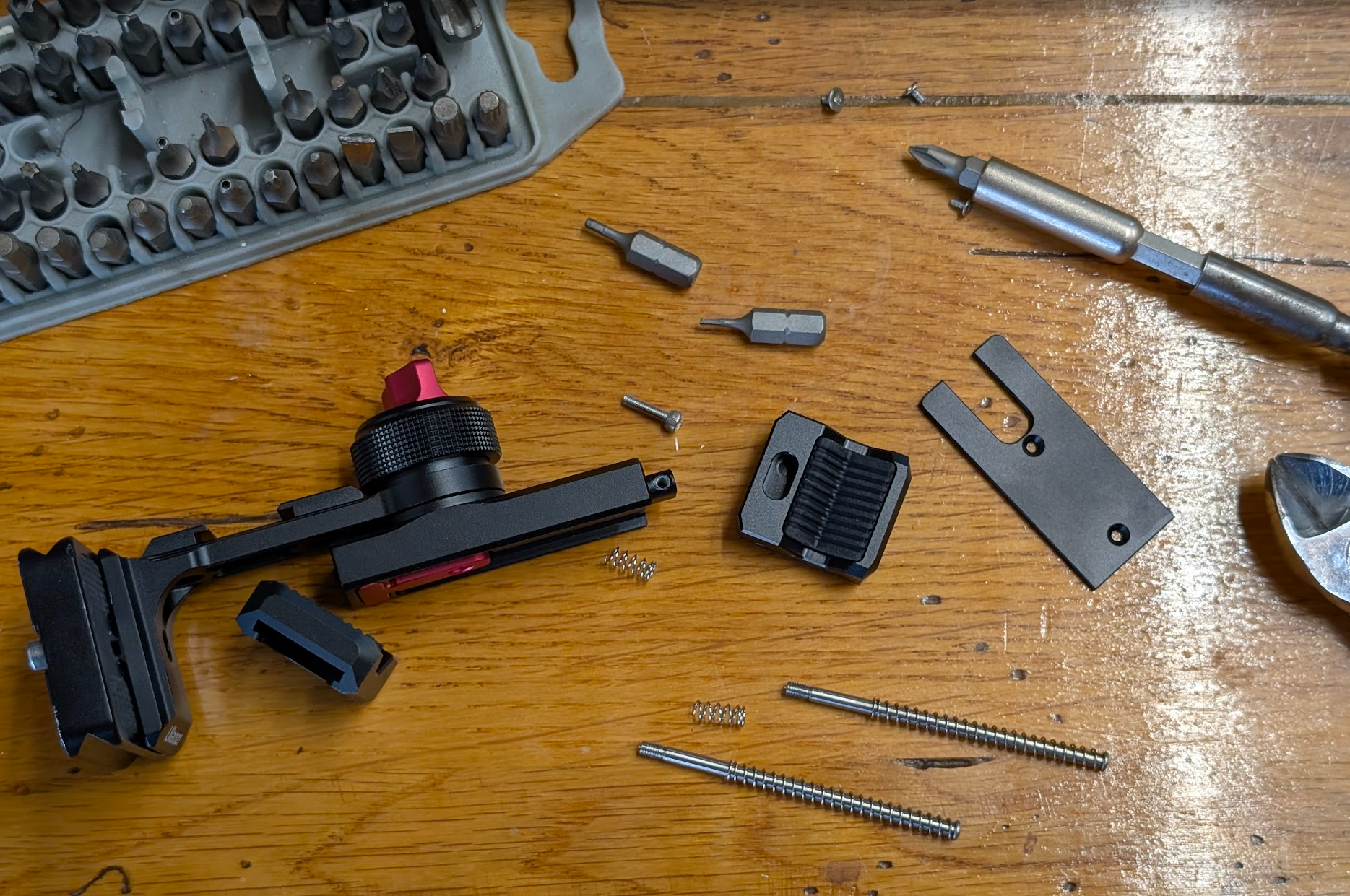

It arrived and was great, but as expected, it did not open enough, so I disassembled it with the plan to just trim a bit off the clamp spring.

Nice machine screws to get the unit open.

Hard to get a photo, but you can clearly see that the only thing stopping it from opening a little wider is the compressed springs themselves.

Trim the springs and open wider is the result...

I took a little more off than the 3mm I needed since I figure this metal bracket will serve me for years to come, and my next phone might be another 2mm wider, so yeah, do the job once and be somewhat future-proofed.

No more having to take the case off to use the mount. Happy baldgeek.